Common Methods

Most 3D printers break an object down into hunderds to thousands of layers, then prints the thin material for each layer. Some of the most common methods to achieve this are FDM, SLA, DLP, and DMLS. Read more about each below.

Image from all3dp.com

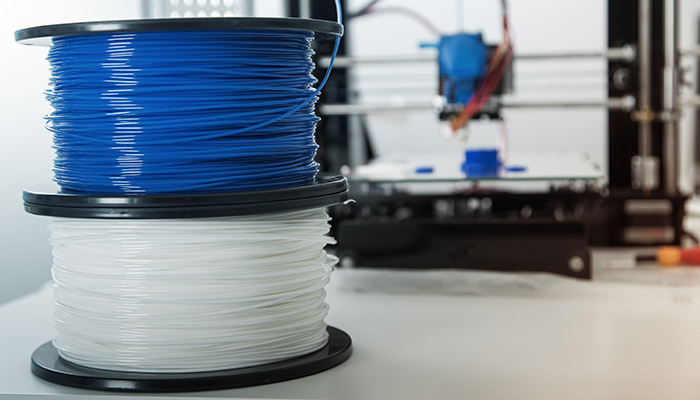

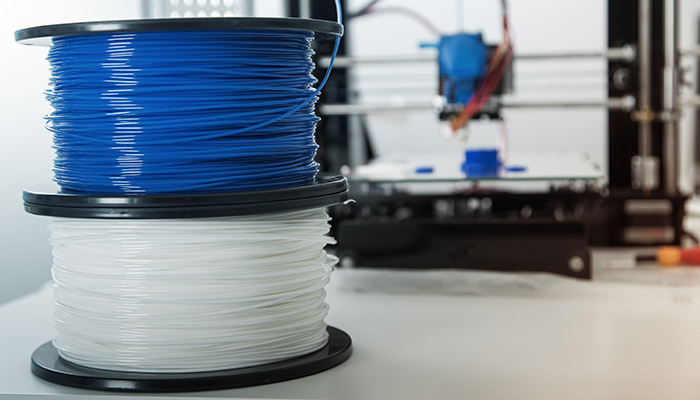

FDM

Fused Deposition Modeling (FDM) is most likely what people picture when thinking of 3D printing. This process invovles liquifying material and building the object layer by layer from the bottom up. Common materials include plastics such as

PLA, ABS, and PETG, however other materials such as nylon and concrete can also be used.

Image from 3dnatives.com

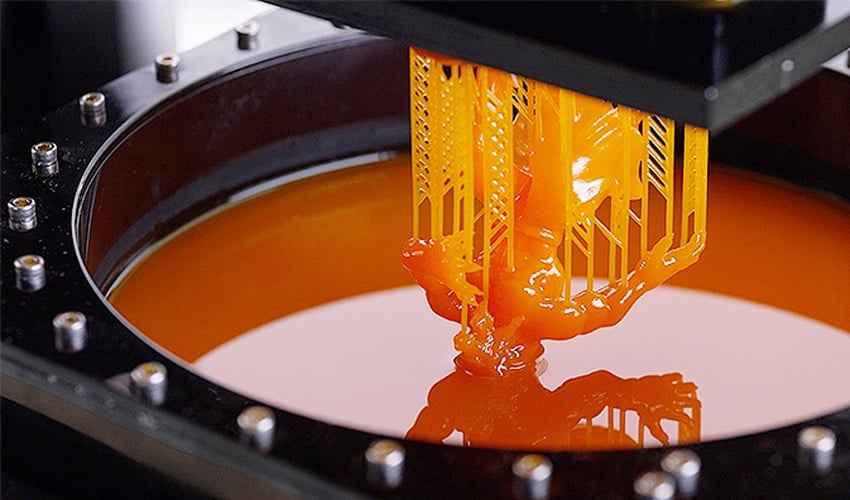

SLA

Stereolithography (SLA) is one of the two most common methods for high detail printing. It involves using a vat of resin and a plate resting atop it. A laser then precisely heats the resin along a path on the plate to create an object from the

bottom up.

Image from mito3d.com and Elegoo

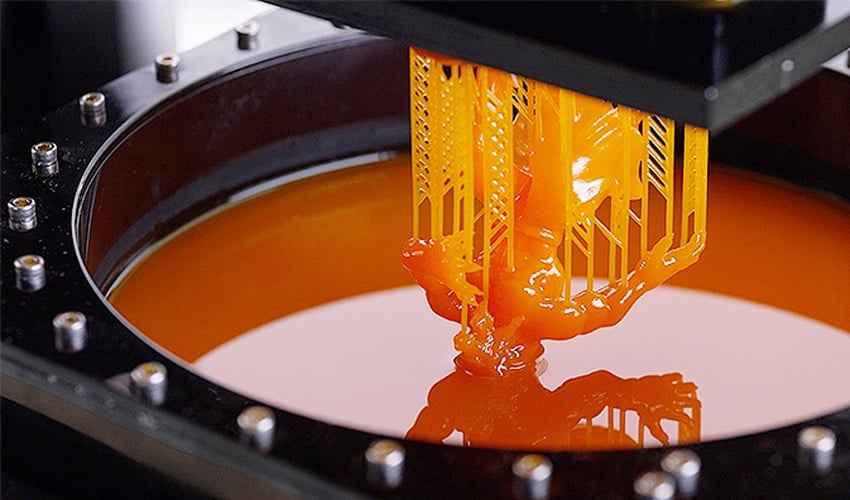

DLP

Digit Light Processing (DLP) is the other of the common methods for high detail printing. It works similarly to SLA, but instead of a laser following a path the DLP projects an image of each layer onto the plate to solidify the resin. This

greatly speeds up the process compared to SLA.

Image from 3dnatives.com

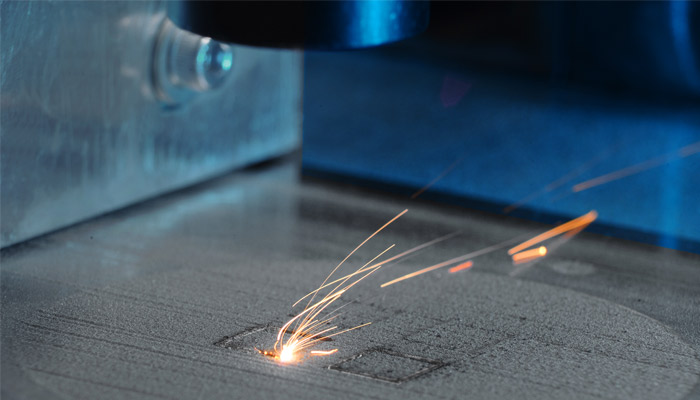

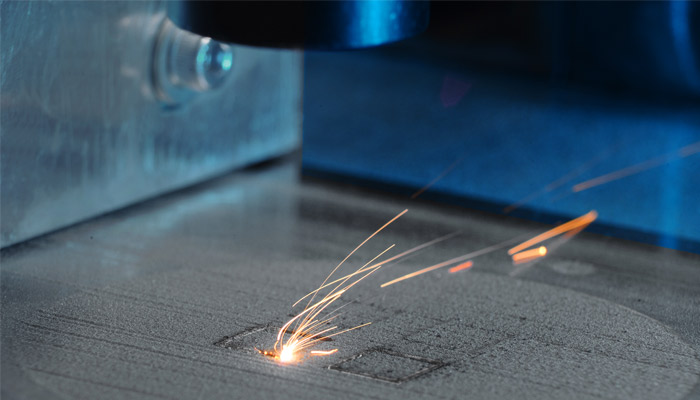

DMLS

Direct Metal Laser Sintering (DMLS) is the primary method for printing with metallic materials. The process involves using a laser to liquify metal powder layer by layer until the desired shape is formed. It is mainly utilized in aerospace and

custom jewelry.

Printable Materials

Materials that are accessable with 3D printing continues to expand as technology grows. Cement, hybrid wood, gold, bio-products, plastic, and even atoms are all able to be printed with modern technology.

Image from 3dnatives.com

PLA

PLA is a very maliable plastic able of adhearing to a variety of shapes. It has one of the lowest melting points of 3d printing materials making it excellent for more elaborate designs, however it is not very durable.

Image from pinshape.com and Kenny Janssens

ABS

ABS is a much more durable plastic able to be food safe compared to its PLA counterpart. This is the same plastic as that which is used to make plastic bottles, electronic and power tool cases, legos, and other common plastic items.

Image from pinshape.com and milostutu

Resin

Unlike plastic, resin is a liquid that solidifies when heated or subjected to certain light spectrums. Because it uses lasers and light to be shaped, extreme detail can be achieved with this material. You see this in products such as

invisalign, tabletop miniatures, or when needing a master object to create molds for manufacturing.

Image from pinterest.com and Sean McKnight

Hybrid PLAs

Due to the success of FDM printing, hybrid PLAs evolved containing mixes of plastic with wood, metal, gold, and other materials to get the maluablity of PLA plastic with more difficult materials.

Image from fortune.com and Alcoa

Metal Powders

DMLS shoots a superheated laser at power to melt it into a solid piece of metal. This allows for highly accurate metallic objects which can accomadate the tight requirements of aerospace.

Use in Industries

Construction

Firms have begun implementing 3D printing in their construciton process to build house shells around the plumbing, electrical, and gas work of a house. This has been seen as a significant reduction in the overall cost of a house allowing for

the possibility of mass-produced affordable housing while also allowing for more design freedom for larger spaces. Ever wanted a castle in your backyard (or maybe as a house?), 3D printing makes these dreams possible at nearly the same cost as

a pool. So next time your significant other brings it up getting a pool, now you can counter with a castle instead.

Image from mudbots.com

Image from all3dp.com and Andrey Rudenko

Image from 3dprint.com and HuaSheng Tengda

Dental

#D printing has swept across the dental industry. Know those commercials you see about the invisible aligners? They grew directly from the capability of 3D printers to take an accurate scan of the patients mouth and print highly detailed

aligners or dentures. Who knows, maybe one day we'll been able to 3D a new tooth to fit snuggly into your mouth.

Image from formlabs.com

Image from formlabs.com

Fashion

Fashion has always been a creative outlet and major economic earner, and as such 3D printing has found its way into the industry. From 3D printed nylon, printing material directly onto cloth, or designing custom and elaborate jewelry, 3D

printing has definitely made its mark.

Image from 3dhubs.com

Image from 3dhubs.com and Cad-Cast.com

Image from 3dnatives.com and Diana Law 3D Printed Jewelry

Aerospace

Due to the low volume of some aircraft or spacecraft, manufacturers aren't keen of the idea of creating a very expensive mold for a single part that might see less than a dozen uses in a year. As a result, 3D printing came onto the scene to

provide custom order parts for the one-off pieces. As a side note, NASA sends metric tons or spare parts to the ISS in order to ensure parts are available when something breaks, but as more research has gone into 3D printing NASA has been able

to send some of those to be an onsite spare part producer and save significant funding due to less trips up to space.

Image from 3dnatives.com and Relativity Space

Image from 3dnatives.com and Relativity Space

Image from 3dnatives.com and Relativity Space

Food

While not quite as prevalent in other industrys, 3D printing still has a place in food! For instance NASA has been researching with 3D printed food for prolonged time in space to avoid moral loss by bland looking sustanence. Certain labs have

been trying to cut down on the environmental effect of cows by using crickets as an alternative protein to impersonate meat or just as an overall protein replacement. Chefs have used 3D printing to develop fun sugar or chocolate structures for

visually stunning desserts.

Image from 3dnatives.com and NASA

Image from 3dnatives.com and Susanna Soares

Image from 3dnatives.com

Hobbyists

Whether you're a household handyperson, tabletop enthusiest, or professional cosplayer, 3D printing has attracted the eyes of many as some of the small scale projects can save money or provide wonderful entertainment. Many simple items or

broken parts could be designed and replaced by a 3D printer at a fraction of the cost (though it might take a minute to cover the cost of the printer). Maybe you have some decorative piece or toy in mind that you'd love to bring into real life,

3D printing can get you there.

Image from pinshape.com and creator Laellee

Image from reddit.com and u/mz4250

Image from reddit.com and u/CancelAtAnyTime